Manufacturing

We believe in technological innovation, and we constantly invest in Research and Development.

Cutting edge hardwares and softwares, combined with our expertise and technical capability, guarantee high quality products. Our advanced testing systems allow prompt, precise and selective intervention, enabling us to take up any challenge our customers may face.

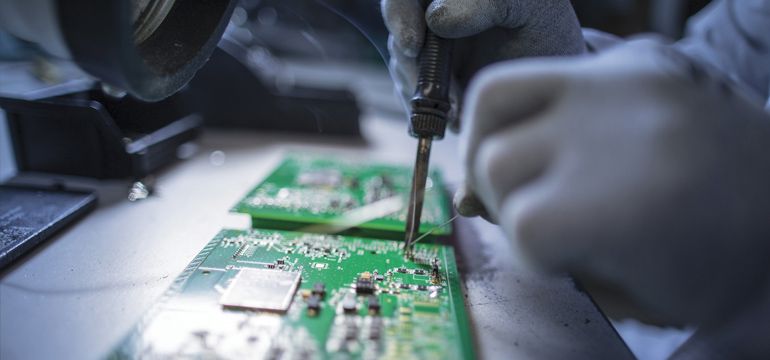

ASSEMBLY

We use automated assembly lines equipped with solder paste screen printer machines with 2D-3D inspection; we also use 10 to 16 headed Pick and Place machines capable of State-of-the-Art components placement, at a speed of 50.000 cph in chip-shooter mode.

High end reflow ovens complete the process ensuring high performances and energetic efficiency.

PCBs are produced with both lead and lead-free finish, in compliance with IPC/JEDEC J-STD-610E standards.

THT assembly area is equipped with pre-forming and pre-assembly departments; manual and semi automatic assembly lines; lead free wave soldering machines, in compliance withIPC/JEDEC J-STD-610E standards; selective soldering systems for completion and point-to-point soldering on the bottom side of products realized with SMT/THT mixed technology.

Thanks to our team’s expertise in terms of efficiency, flexibility and control, we are able to streamline each and every process.

Finished products are assemblied and tested in line or in dedicated workstations, thanks to softwares providing guided assembly. GFC uses State-of-the-Art equipment to handle and assembly mechanical, electromechanical and plastic components, allowing us to deliver a finished product based on the customer’s specifications.

TESTING

In GFC every production process is checked according to IPC 610F standard.

Our State-of-the-Art optical inspection systems, equipped with laser and high speed digital opticals for 3D measurement, check every SMT production, allowing our specialized technicians to promptly implement corrective actions.

The accurate and prompt inspection is able to guarantee high quality standard regardless of the board and circuit complexity.

State-of-the-Art parametric test hardware and software systems offer automatic testing specifically customized to meet clients’ needs, and are able to locate and diagnose any critical issues before moving into the next phase.

In-circuit testing individually checks every component, ensuring they perform to their specification.

GFC experienced and trained staff is able to use the most innovative Work and Repair systems to check and refinish 100% of THT production.

SPECIAL PROCESSES

Our highly skilled and certified staff is able to rework and repair even the most challenging request, both during the testing phase and on the finished product.

We use the most advanced technologies in the field, and our semiautomated systems are able to re work exotic SMT components.

Conformal coating process assures oxidation prevention thanks to robotic systems providing total or selective epoxy coating. Curing systems provide resin drying under controlled temperature.

On customers’ request we can perform burn-in testing, by putting all the components of the board through climatic stress in environmental chambers.